Company Advantages

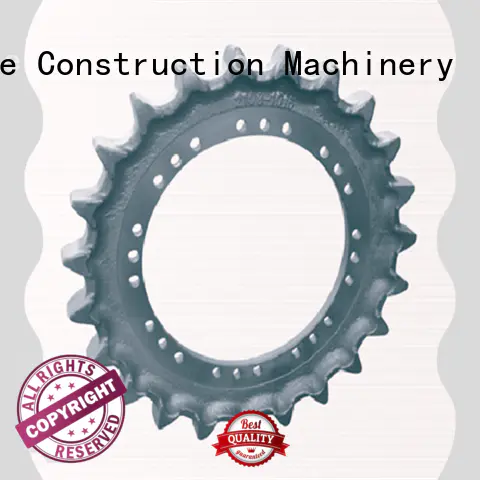

1. Laike sprocket track is made of superior raw materials which are selected from qualified vendors. It is able to support the entire upper weight of the bulldozer

2. It plays an important role in our customers' business, and its market prospect is very broad. It ensures no cracks, notches, or holes on its surface

3. The product works stably under the reversible circuits. Its forward and reverse contactors are equipped with electric interlocks and mechanical interlocks to ensure smooth operation. It is inspected and approved for dimensional compliance

4. The tight weaving of the microfibers does cause any liquid to form beads on the surface of the fabric and stay for a short time, rather than soaking immediately. It allows the dozer easily accessible for regular maintenance

Company Features

1. Having been strictly tested, our excavator sprocket has gained more and more popularity.

2. Our goal is to achieve industry-leading operational performance through strategic development initiatives, technological innovation, and an accelerated shift to a new development mode highlighting quality and efficiency.