Company Advantages1. Laike sprocket segment is developed in cooperation with our customers by our in-house engineers using CAD, 3D simulation, physics rendering, etc.

2. Laike track drive sprocket undergoes the following production processes: the preparation of metal materials, cutting, welding, surface treatment, drying, and spraying.

3. Each Laike track drive sprocket is tested and checked. It adopts certified and calibrated instruments to finish the tests such as chemical composition tests and environmental tests (hot, cold, vibration, acceleration,etc.)

4. The product is of high precision. It is manufactured by a variety of specialized CNC machines such as a cutting machine, punching machine, polishing machine, and grinding machine.

5. The product stands out for its fatigue resistance. It can withstand a given number of cycles without breaking under high stresses.

6. The product features high precision. The machines are equipped with control probes that allow the dimensions to be checked while the piece is still in the machine, thus avoiding repositioning that would decrease the required precision.

7. The product features high accuracy. All its parts have been measured by means of the advanced 3D coordinate measuring device.

8. The product has great surface quality. The destruction of the surface will be not easily susceptible to wear such as cracks, notches, holes or even broken off.

9. The product is durable enough. It has been tested by an accredited laboratory to be resistant from salt spray and chemicals such as petroleum, diesel, and pesticides.

10. Strong technical force facilitates the bulk production of sprocket segment which also ensures the high business efficiency.

11. The success of Laike can not be achieved without the efforts of all the staff.

12. An appropriate programme of quality control (QC) must be implemented in Quanzhou Laike Construction Machinery Co.,Ltd.

13. Laike is able to produce high quality sprocket segment with a high efficiency.

14. Quanzhou Laike Construction Machinery Co.,Ltd has established a sound quality control system to make sure the quality of the product.

15. Quanzhou Laike Construction Machinery Co.,Ltd's sales department implements a perfect modern management system.

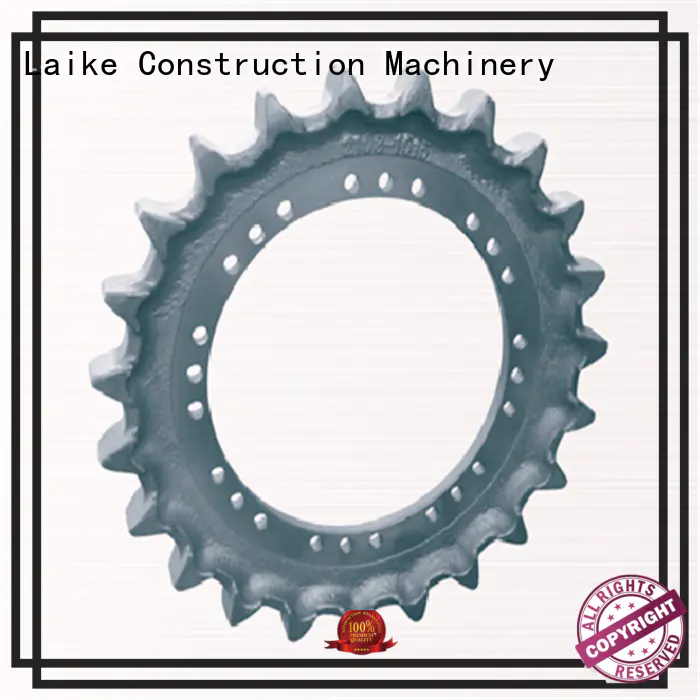

affordable price sprocket segment reasonable design transfer engine power for excavator

sprocket segment

Type:reasonable design

、 Type1:handpick materials

、 Type2:stable performance