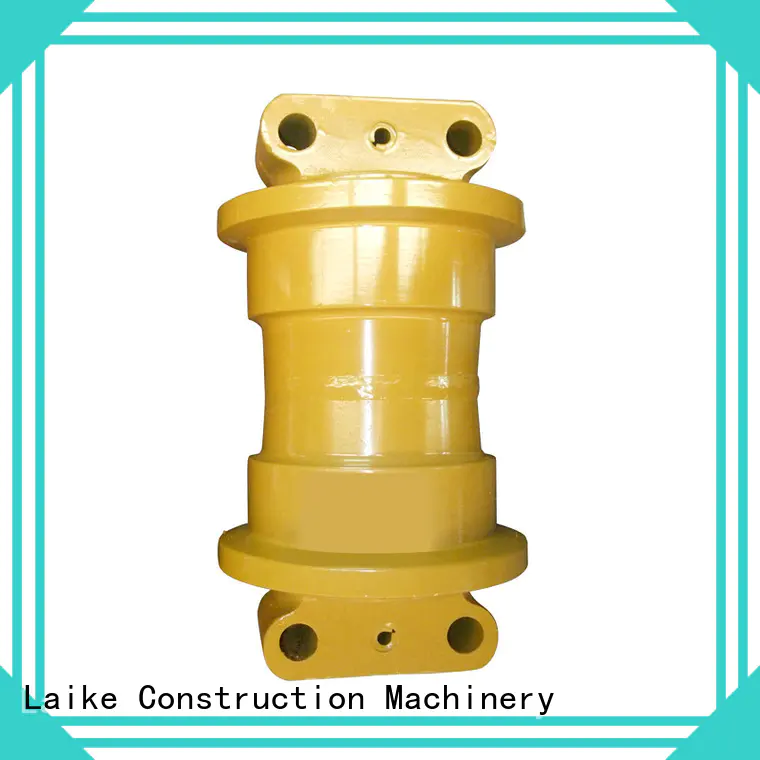

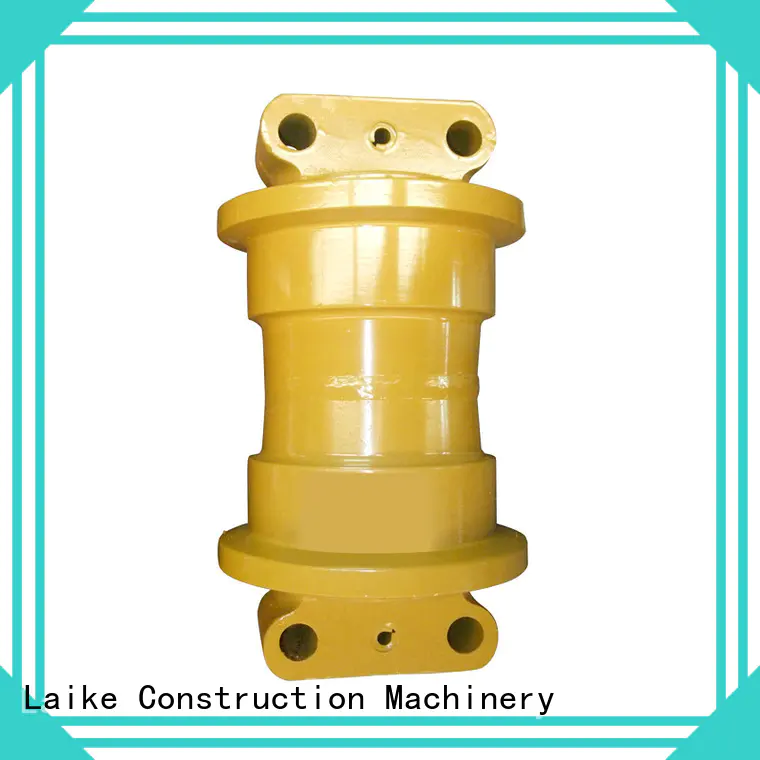

Company Advantages1. Laike excavator bottom rollers is professionally designed. It is designed with the help of a modern 3D software environment which is accompanied by a complete 2D documentation necessary for the production of the machine.

2. Laike excavator bottom rollers is precisely manufactured. During the production, it adopts various kinds of CNC machines such as cutting machine and punching machine.

3. Most of Laike excavator bottom rollers are produced by hand. This process is carried out by our highly qualified employees ensuring absolute precision in this sensitive process of making original molds.

4. The production of Laike excavator bottom rollers has been optimized. It is produced with the help of modern IT-based processes such as the solidification simulation.

5. In the manufacture of Laike excavator bottom rollers , it has to go through a series of production processes, including metal materials CNC cutting, milling, welding, and assembly.

6. During the production of Laike flange roller , it has gone through heat and surface treatments: hardening, induction hardening, chemical browning, and electroless nickel plating.

7. The product stands out for its low energy consumption. By adopting energy-saving technology, its ingenious circuit design can effectively minimize the loss of energy due to transient currents.

8. This product is non-toxic. The materials and parts used in it have been tested to guarantee no harmful element is contained.

9. The product has fine strength and elongation. A certain amount of elasticizer is added into the fabric to enhance its capacity of tear resistance.

10. Laike promises that we will check every detail from the material selection to package.

11. Quanzhou Laike Construction Machinery Co.,Ltd fully implements the quality management system, laying the foundation for future innovation and development.

12. Quanzhou Laike Construction Machinery Co.,Ltd will provide professional and comprehensive technical support for flange roller .

13. By serving clients well, Laike has won a lot of praises.

14. With complete production lines, Laike guarantees the high efficiency of flange roller production.

15. The quality flange roller products is the fundamental to the development of enterprises.

best flange roller heavy-duty for excavator

flange roller

Type: