Company Advantages1. The production stages of Laike undercarriage sprocket involve a few aspects. It has to undergo die casting, finish machining, CNC machining, surface treating, and electrostatic spraying.

2. Laike bulldozer sprockets has to go through the following production stages: CAD software design, fabrication of aluminum frame, track creation, and installation of all accessories.

3. The quality inspection of Laike undercarriage sprocket will be carried out throughout the production stage. It will be checked for the insulation of wires, the performance of insulation resistance, nominal voltage, and other electric components.

4. The product can continue to operate. It can be used for 365 days a year, 24 hours a day, except for maintenance.

5. The product is reliable in operation. It can constantly perform its tasks while holding the highest level without any failure.

6. This product is resistant to high temperatures. It is made of a heat-resistanting material with a high melting and high decomposition point.

7. 'This product is very easy to remove and re-install. It functions very well and fits well my machine.' - Said one of our customers.

8. After times of wear, this product is guaranteed that it will be not subject to problems like color fading and paint flaking off.

9. One of our customers said that this product is able to stand up the test of time after times of wear from the machine.

10. The product can last over time. Even used in the hardest machinery environments, it still can function well with high performance.

11. The product is able to stand up the test of time and not easily fail when applied to the machine.

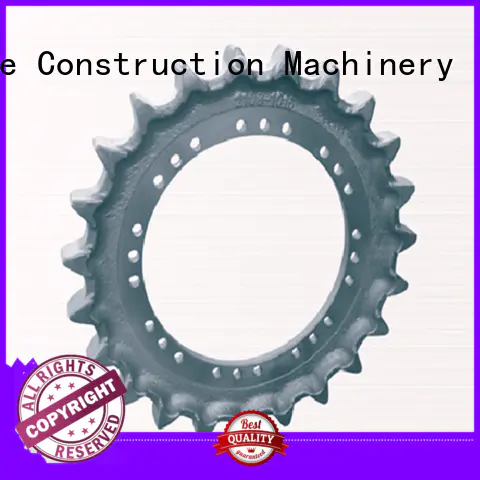

custom made bulldozer sprockets reasonable design transfer engine power for bulldozer

bulldozer sprockets

Type:reasonable design

、 Type1:stable performance、 Type2:handpick materials