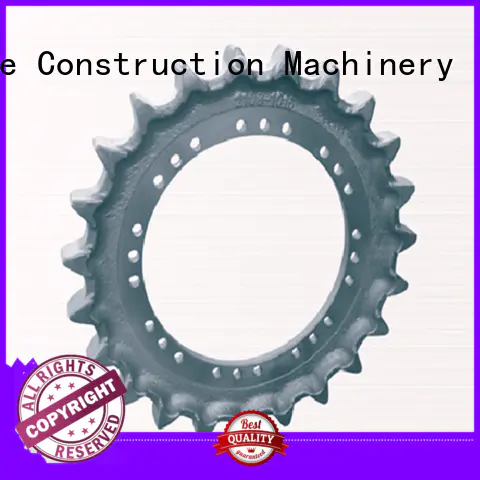

Company Advantages1. Laike excavator sprocket rim will go through a range of quality tests. They are fitting test, dry and wet crocking test, seam strength test, and the whole piece's quality inspection.

2. The tests for Laike sprocket segment include different aspects. They are tear strength testing, biomechanical comfort testing, fire protection testing, and shock absorption testing.

3. The design of Laike excavator sprocket rim has covered various factors. They involve the principle of structural mechanics, ergonomics (referring to human's physiological structure development). )

4. The product is wear-resistant, durable to use.

5. Compared with the competitors, the product is more reliable in quality and performance.

6. The excellent quality control throughout all stages of production ensures top quality of the product.

7. Precision is of supreme importance in the machining and fabrication of this product. So people can set assured this product is able to meet the rigorous accuracy requirements.

8. The product is completely compatible with the specific needs of a machine or device for its superior reliability and durability.

9. The product can be totally recycled. This means that people can reduce their costs in terms of raw materials cost.

10. The product has relatively few moving parts, which means it will have a longer lifespan, which can be used for years.

11. When I bought this product, I think it can last for a long time. So far, I couldn't find any failure happened on my machine. - - Said one of our customers.

12. 'This product is very easy to remove and re-install. It functions very well and fits well my machine.' - Said one of our customers.

custom made sprocket segment handpick materials popular for bulldozer

sprocket segment

Type:handpick materials

、 Type1:stable performance、 Type2:reasonable design