Company Advantages1. The materials used for Laike chain idler wheel have been tested. The testing procedures include tensile testing, toughness or brittleness testing, hardness testing, infiltrate testing and testing through radiations.

2. During the development of Laike chain idler wheel , several disciplines have been adopted. It is developed under the knowledge of mechanical engineering, physical mechanics, hydraulic transmission and control, and so on.

3. Laike chain idler wheel undergoes necessary inspection in the independent laboratory. It is scrutinized with the help of complete checking equipment to ensure it fits perfectly with the phones.

4. The quality of Laike chain idler wheel will be authenticated using professional inspection approaches, including visual inspection, non-destructive inspection, and metallographic examination.

5. The manufacture of Laike chain idler wheel generally includes the following stages. They are mainly CAD/CAM design, procurement of raw materials, fabrication, welding, spraying, commissioning, and measurement.

6. The quality of Laike chain idler wheel is monitored by inspectors and testers. Its individual parts such as the motor, engine, and hydraulic system all tested to meet the standards set by the company.

7. The product is quality certified for long life.

8. The product exceeds industry standards in performance, durability and usability.

9. The quality of the product is guaranteed by our state-of-the-art facilities and advanced technology. Its quality has passed the strict test and is examined frequently. Thus its quality has been widely accepted by the users.

10. It is considered as a hot product as it has huge economic benefits.

11. The product finds its application in various industries.

12. The product has gained a high reputation globally thanks to its huge economic benefits.

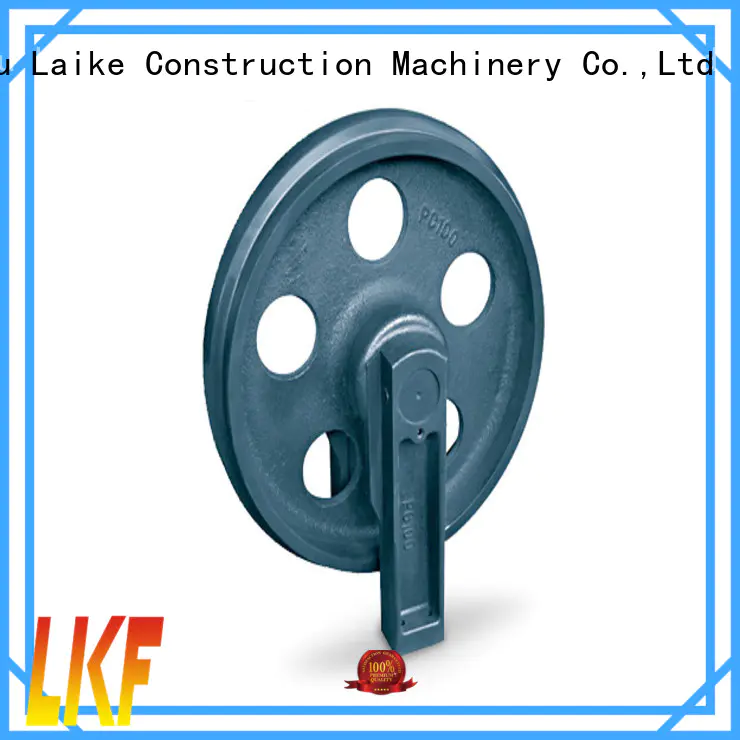

Excavator Idler wheel front idler guide roller Laike Construction Machinery

track idler

Type:high-quality

、 Type1:front roller

、 Type2:custom

、 Type3: