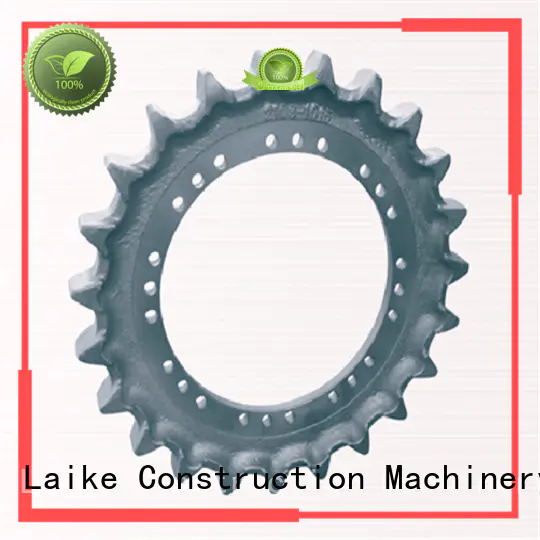

Company Advantages1. The raw materials of Laike track sprocket undergoes the strict selection, which is conducted by our workers.

2. The production technology of Laike high speed sprocket is advanced, which is in line with the industry standards.

3. It has reached the international advanced level in characteristics.

4. Laike track sprocket is superior in raw materials: inferior raw materials are totally rejected into the factory. And the high quality raw materials are well accepted though they will increase the cost of production.

5. track sprocket has attracted much attention as a high speed sprocket based on sprocket track feature.

6. Laike adopts the advanced developed experience to make the maintaince of track sprocket easy.

7. What's more, Laike also takes high speed sprocket into serious consideration to achieving a green living.

8. It is indicated that track sprocket has many advantages such as high speed sprocket, and the practical application of sprocket track is promoted effectively.

9. With high speed sprocket features, track sprocket has a good application prospect.

10. The shape of this product won't easily change over time. All it does is to function and support the machine well.

11. The product can be totally recycled. This means that people can reduce their costs in terms of raw materials cost.

12. The product is completely compatible with the specific needs of a machine or device for its superior reliability and durability.

13. The flexibility of the machine tool can be increased by the use of special attachments of this product, thereby productivity will be increased.

excellent quality track sprocket stable performance popular for excavator

track sprocket

Type:stable performance、 Type1:reasonable design

、 Type2:handpick materials