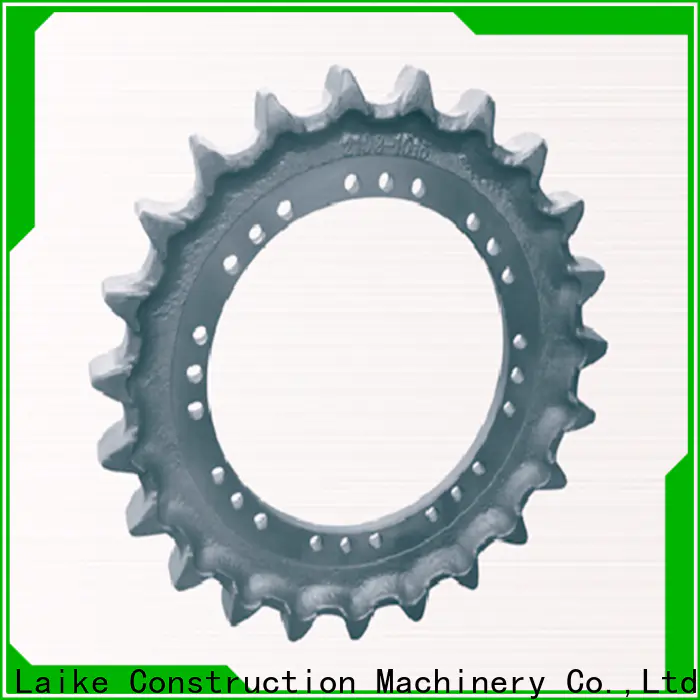

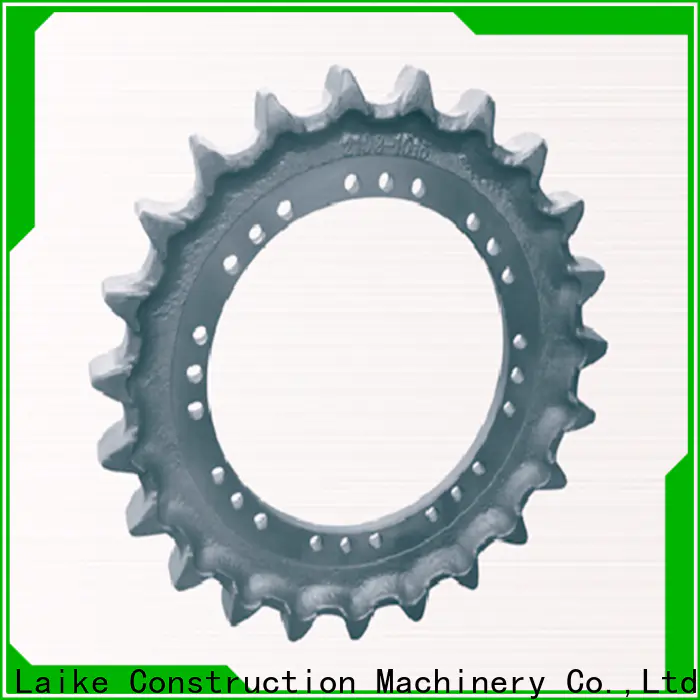

Company Advantages1. The production of Laike sprocket rim is of high standards. The production of this product is strictly in line with the workflow machine parts such as turning, milling, and boring.

2. During the production, the quality of Laike excavator drive sprockets is strictly scrutinized in terms of materials, cutting, welding, turning, milling, grinding, and surface treatment.

3. Laike excavator drive sprockets has to go through the following production stages which include materials preparation, turning/lathing with both traditional and CNC milling machines, wire EDM, adjusting and polishing, and mechanical assembly.

4. Laike excavator drive sprockets has passed the following physical and mechanical tests. These tests include a strength test, fatigue test, hardness test, bending test, and rigidity test.

5. The manufacture of Laike excavator drive sprockets is of high efficiency. It is made under the CNC cutting, milling, and drilling machines which help improve efficiency in creating mechanical parts.

6. Laike sprocket rim is treated well. It has gone through following procedures include slotting, straightening, micro-bead blasting, tumbling, ultrasonic and steam cleaning, as well as chemical and microdot marking.

7. The product features high wear-resistance. When exposed to grinding, knocking or scratching, it will not easily damage the surface.

8. The product is designed to carry either large loads. It can afford maximum load capacity in the smallest possible space.

9. The product features good deformation resistance. When a sufficient load from a machine is applied to it, it will not happen to change shapes.

10. The product features great impact strength. It has been measured by allowing a pendulum to strike a grooved machined test piece and measuring the energy absorbed in the break.

11. The product is highly chemical resistant. It is treated with a protective chemical coating or with protective paintwork to prevent corrosion.

12. The product features high surface hardness. It has passed the heat treatment process by adding a certain amount of nitrogen to the surface.

13. This product is currently enjoying an enormous appeal with the general public’s initiatives to prevent making use of paints that involve damaging solvents as well as harmful chemicals in its application.

14. Once users try this soft product, they are likely to find that its comfort is just as appealing as the colors and styles that it is available in.

15. It is generally preferable for allergy sufferers, allowing them to sleep comfortably at night without the worry of runny eyes or stuffy noses.

high quality sprocket rim factory for excavator

sprocket rim

Type: