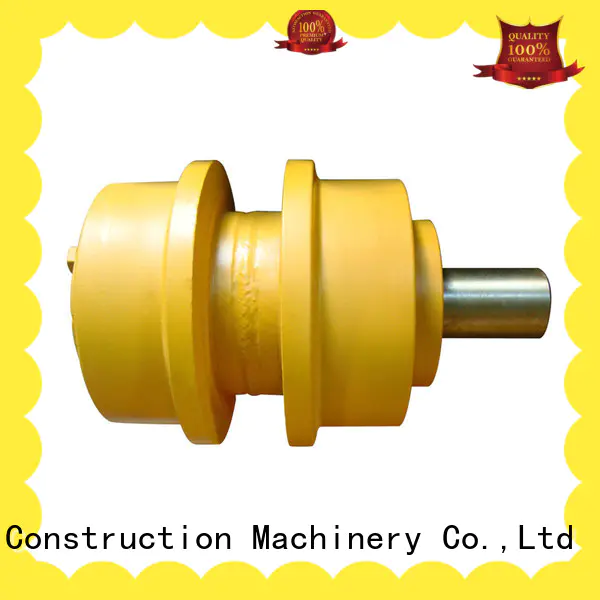

Company Advantages1. Laike upper roller excavator has gone through sophisticated manufacturing processes. These processes include selecting ingredients, mixing, vacuum, solid, sanding, curing, polishing, etc.

2. The surface treatment of Laike track carrier rollers consists of several stages, including rust, grease, and oxidization resistant treating processes. All these processes are carefully done to guarantee its resistant capacity.

3. A series of quality tests for Laike track carrier rollers will be conducted by the QC team. Its wires and cables, plug and socket, switching power supply will be strictly tested by specific machinery.

4. Laike track carrier rollers satisfies the general requirements for the safety of household and similar electrical appliances. It will be tested for safety issues including insulation, electric leakage, and short circuit.

5. The product has the advantage of high precision. The high technology CNC machines have guaranteed the highest accuracy of mechanical parts.

6. The product features high wear-resistance. When exposed to grinding, knocking or scratching, it will not easily damage the surface.

7. The product is highly resistant to rust. Its surface has been treated with an oxide protective layer to prevent from the damage of wet environments.

8. Due to its excellent characteristics, this product is well received by customers and is used more and more in the market.

9. The market share of this product is growing, showing its wide range of market applications.

10. This product has many advantages, so there will be more and more applications in the future.

11. The product has gained great popularity in the market and enjoys a vast market application.

12. Due to its remarkable economic return, the product is now widely used in the market.

high-quality track carrier rollers oem from best manufacturer for bulldozer

track carrier rollers

Type:oem

、 Type1:top

、 Type2:wholesale