Company Advantages1. The most of Laike bulldozer track chains is manufactured on the Flexo-Folder-Gluer (FFG) machines which are combining printing, die-cutting, folding and gluing. Those processes can be also performed on separate machines.

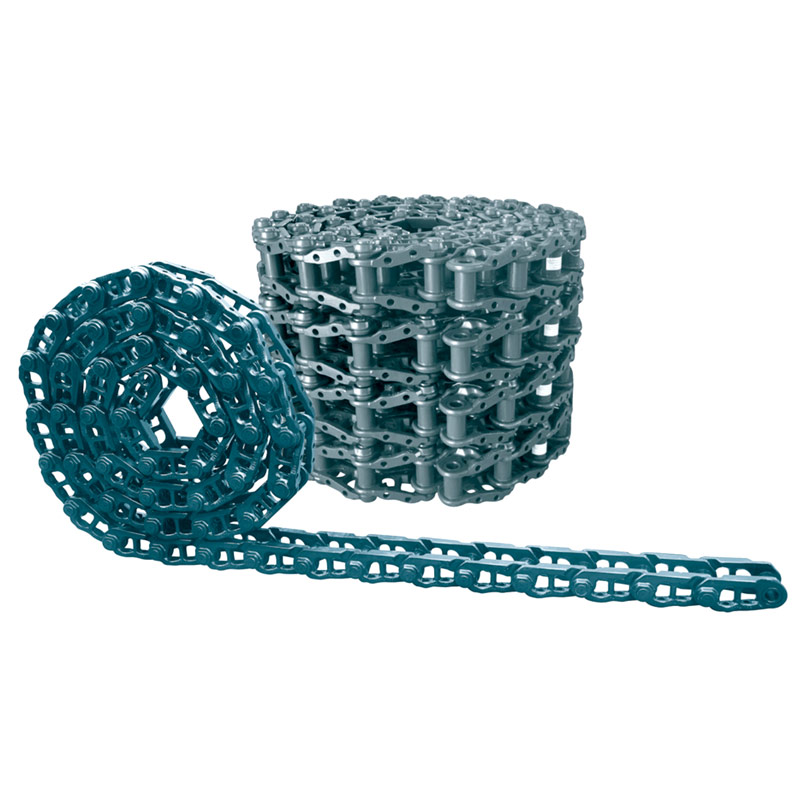

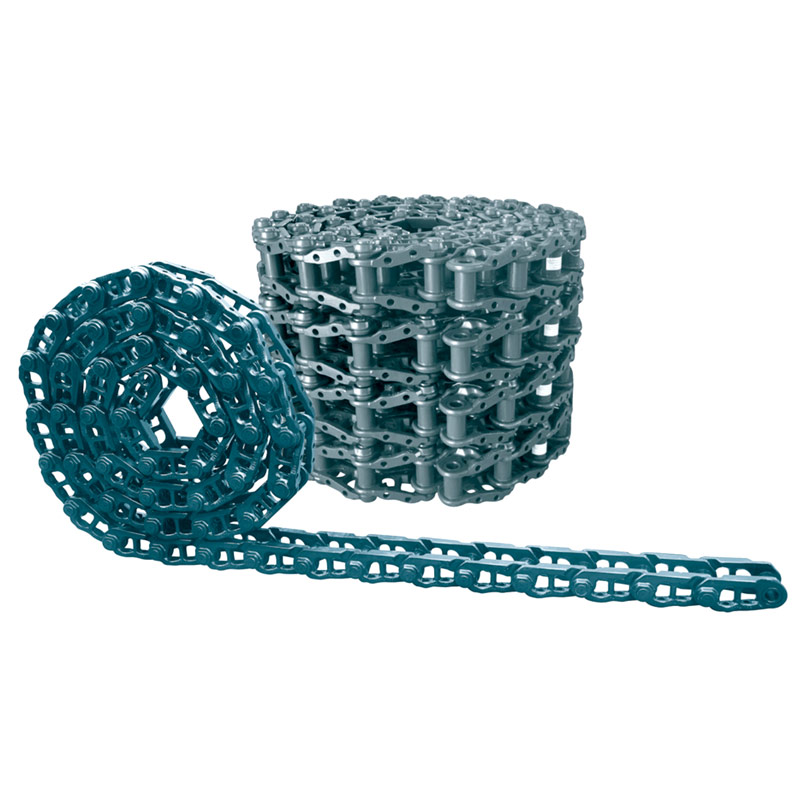

2. The mechanical components of Laike bulldozer track chains are manufactured in virtue of many high technologies. They are produced under highly precise machines, including CNC machines, electroplating spraying equipment, and surface polishing machines.

3. Different machining approaches are used in processing mechanical parts of Laike bulldozer track chains . These mechanical parts, including engine, motor, and hydraulic components, will go through thermal treatment, honing machining, or wire cutting based on their actual usages and structures.

4. The necessary tests for Laike bulldozer track chains have been conducted. These tests include voltage compatibility, electromagnetic safety, electric shock hazards, and materials insulation performance.

5. Safety check for Laike bulldozer track chains is carried out by the QC team during the production. It will be checked for its electrical safety includes input voltage, amperage, anti-surge-current capability, etc.

6. The product is the primary choice of customers worldwide for its high performance.

7. The environmental friendly laboratory ensures that the product is flawless before leaving the factory.

8. Our professional team implements quality control system to meet the most strict quality standards.

9. The professional technical team conducts a comprehensive quality control for this product in the production.

10. This product is functional, which caters to the customers' needs.

11. The accurate inspection process guarantees that the product meets with the international quality standards.

12. This product is suitable for any season. Its material is more tightly woven and weighs more, making it pleasantly soft and comfortable - ideal for year-round comfort.

13. The product is a safe choice for most workers. It can reduce human intervention mistakes or even dangerous phenomenons caused by malfunction.

14. Not only does this product offer environmental benefits by reducing waste and pollution, but it also offers major energy savings for owners.

high-quality track link wholesale for customization

track link

Type:high-quality、 Type1:high-end

、 Type2:fine workmanship