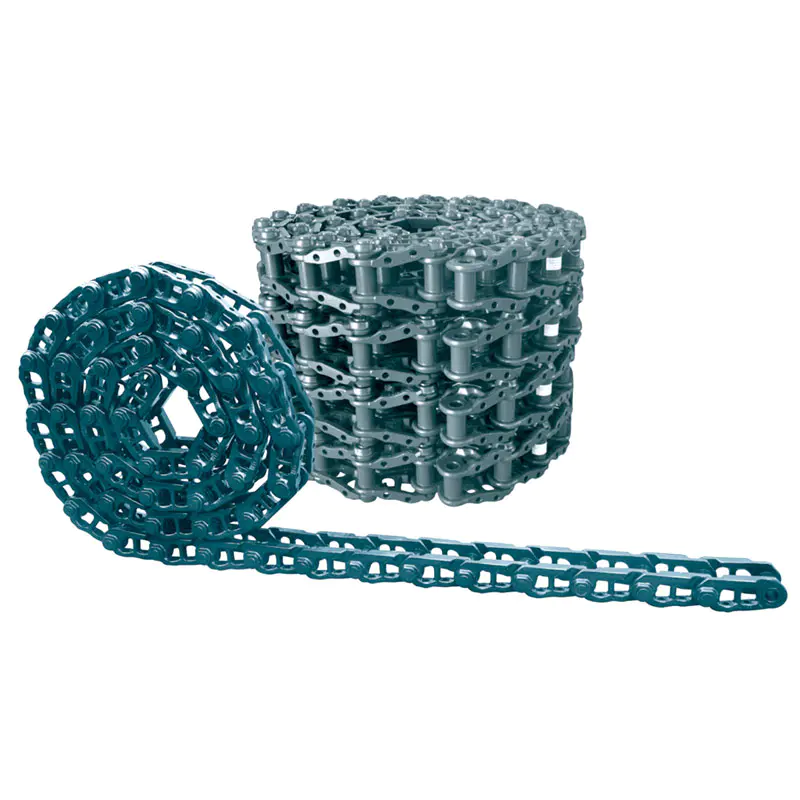

excavator track shoe

How about sales of track chain under Laike ?

2020-05-31

In many years spent producing track chain, we have never compromised. Our commitment to creating a lasting interest that does not fade over time to our customers and to creating products that can be of use and not just attractive have never been changed. It is this consistency that makes our brand - Laike , known and appreciated by more and more customers, enabling us to achieve new sales growth every year. We believe that with our continuous improvement and innovation, the domestic and foreign markets for our brand are both promising.

Quanzhou Laike Construction Machinery Co.,Ltd is a manufacturer well recognized by the public. We have strong competitiveness thanks to years of experience in the business of undercarriage sprocket. The track link series is widely praised by customers. Laike bulldozer track roller is manufactured in compliance with the industry standards using premium raw materials. It is meticulously designed under the help of computer-aided drafting (CAD). It has a low fabric shrinkage rate. The fabric has been treated under steam or atomizing, extruded by machine, and dried, which makes the shrinkage rate drop to 1% or lower. It is able to support the entire upper weight of the bulldozer.

Under the purpose of upgrading the production process, we carry out a process innovation method. We have newly introduced new equipment and technology used in manufacturing, which greatly increases production efficacy.

Quanzhou Laike Construction Machinery Co.,Ltd is a manufacturer well recognized by the public. We have strong competitiveness thanks to years of experience in the business of undercarriage sprocket. The track link series is widely praised by customers. Laike bulldozer track roller is manufactured in compliance with the industry standards using premium raw materials. It is meticulously designed under the help of computer-aided drafting (CAD). It has a low fabric shrinkage rate. The fabric has been treated under steam or atomizing, extruded by machine, and dried, which makes the shrinkage rate drop to 1% or lower. It is able to support the entire upper weight of the bulldozer.

Under the purpose of upgrading the production process, we carry out a process innovation method. We have newly introduced new equipment and technology used in manufacturing, which greatly increases production efficacy.

Custom message