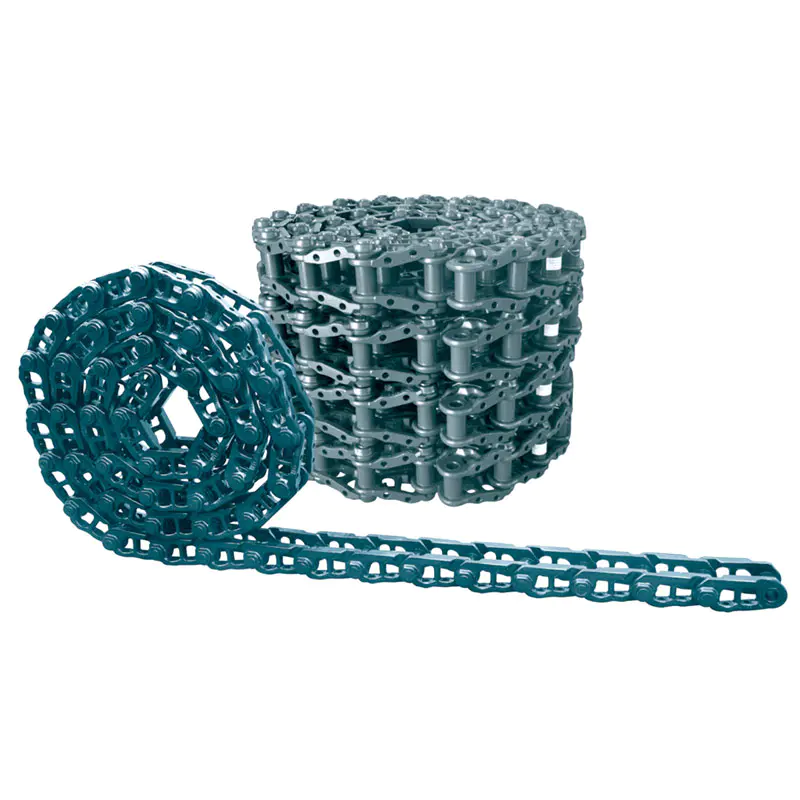

excavator track shoe

How are materials used by Laike Construction Machinery for producing idler wheel?

2020-07-18

Our responsibility for quality starts with the selection of materials. We have a responsibility to make sure our suppliers take care of their materials. We use industry-wide guidelines to assess their materials and select only the best. And before we put the raw materials into production, we have a materials testing procedure. Our expert team will carefully test the materials to ensure that they are suitable for processing and meet the safety and quality requirements. Our strict quality control over raw materials ensures you only get high-quality and high-performing idler wheel.

Years of focus on the development and production of undercarriage sprocket has made Quanzhou Laike Construction Machinery Co.,Ltd a well-known manufacturer in China. Laike Construction Machinery provides a wide range of sprocket rim for customers. The production of Laike undercarriage sprocket involves these processes: the procurement of raw materials, welding and fabrication of the base or frame, machining of component parts, painting, and assembly. The product is leading the market trend and has a bright market prospect. It offers long life throughout abusive use.

We not only take part in the charitable giving but also we devote ourselves to volunteering in the communities, so as to make our society better. Inquire online!

Years of focus on the development and production of undercarriage sprocket has made Quanzhou Laike Construction Machinery Co.,Ltd a well-known manufacturer in China. Laike Construction Machinery provides a wide range of sprocket rim for customers. The production of Laike undercarriage sprocket involves these processes: the procurement of raw materials, welding and fabrication of the base or frame, machining of component parts, painting, and assembly. The product is leading the market trend and has a bright market prospect. It offers long life throughout abusive use.

We not only take part in the charitable giving but also we devote ourselves to volunteering in the communities, so as to make our society better. Inquire online!

Custom message