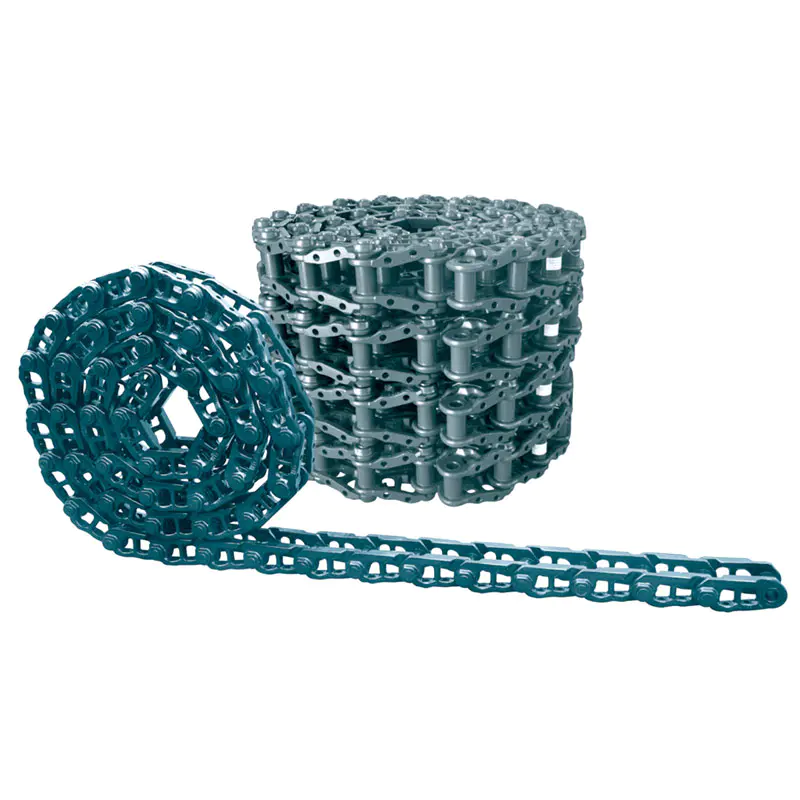

excavator track shoe

How did Laike Construction Machinery design sprocket rim?

2020-06-16

At Quanzhou Laike Construction Machinery Co.,Ltd, the design process of sprocket rim has several stages and steps, and each of them can be methodized and be done regularly. Typically, there are 4 steps for us to carry out the design procedure. Firstly, we start with gathering the necessary information and requirements from customers. This is usually achieved by either a face-to-face meeting with the client, a questionnaire (on- or off-line), or even a Skype meeting. Secondly, this step is mainly focusing on design creation. Having got in-depth research of customers and their products, target market and competitors, we will begin brainstorming to decide the colors, shapes, and other elements. The next step is evaluating the design work and doing the refinement if possible. Customers should provide any feedback they may have once seeing the design. The last step is to apply the confirmed design work into the production formally.

Under advanced equipment and mature technology, Laike Construction Machinery has become an advanced manufacturer of idler wheel. The track roller series is widely praised by customers. Laike excavator idler wheel is carefully designed based on our many years of experience. It easily resists shock loads and torsional forces normally incurred by the bulldozer. This product has a soft and luxurious feel that makes you sleep well at night. This is great for any room in the house. Without sharp edges, this product is safe to use.

Sincerity to our customer is the most important in Laike Construction Machinery. Welcome to visit our factory!

Under advanced equipment and mature technology, Laike Construction Machinery has become an advanced manufacturer of idler wheel. The track roller series is widely praised by customers. Laike excavator idler wheel is carefully designed based on our many years of experience. It easily resists shock loads and torsional forces normally incurred by the bulldozer. This product has a soft and luxurious feel that makes you sleep well at night. This is great for any room in the house. Without sharp edges, this product is safe to use.

Sincerity to our customer is the most important in Laike Construction Machinery. Welcome to visit our factory!

Custom message