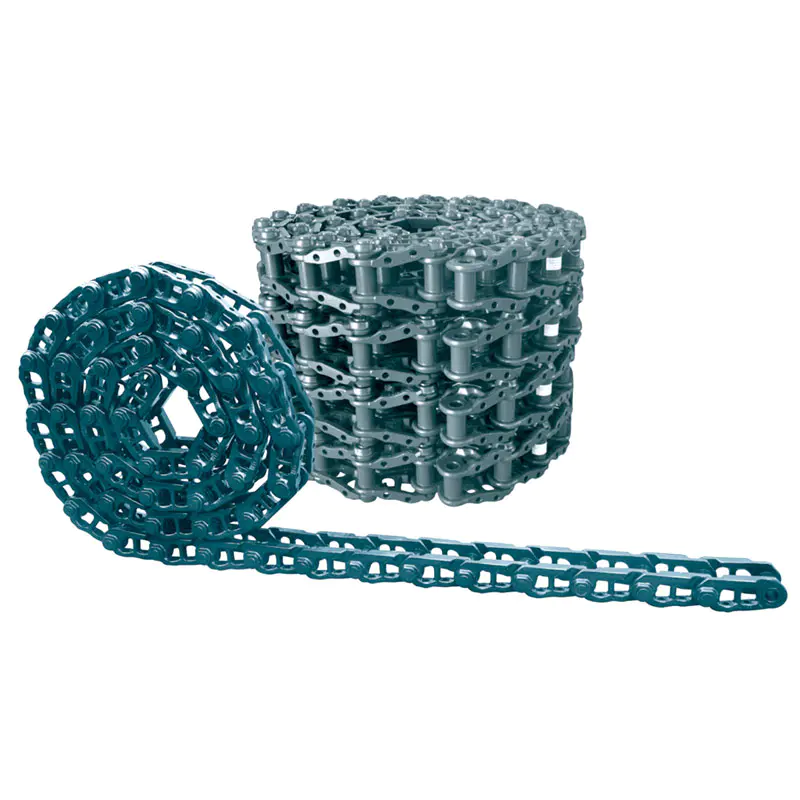

excavator track shoe

How does Laike Construction Machinery manufacture idler wheel?

2020-07-18

In order to ensure the high performance of idler wheel, strict quality control is applied in the manufacturing process. Providing world-class manufacturing process and exceeding customer expectations are the promise and goal of Laike . We have advanced production lines and various testing equipment for product processing, which help improve the efficiency of several manufacturing process, like prototyping, material sourcing. Through manual adjustments, the product can meet the requirements of a high pass rate.

Quanzhou Laike Construction Machinery Co.,Ltd, being one of the leading manufacturers of excavator idler wheel in domestic markets, has evolved into a giant company. Laike Construction Machinery provides a wide range of track roller for customers. Laike bulldozer track chains is composed of various electric components. Every part of the product will be seriously considered, including the gears, pistons, engine, and other moving parts. It is meticulously designed under the help of computer-aided drafting (CAD). The product is sturdy and tough. The cabinet body and parts are securely fastened with heavy duty cabinet screws to ensure very strong construction. As a wearing component, its excellent strength considerably lower maintaining costs.

We proactively conduct sustainable operations. For instance, we are constantly introducing advanced production technologies to reduce water waste and CO2 emissions.

Quanzhou Laike Construction Machinery Co.,Ltd, being one of the leading manufacturers of excavator idler wheel in domestic markets, has evolved into a giant company. Laike Construction Machinery provides a wide range of track roller for customers. Laike bulldozer track chains is composed of various electric components. Every part of the product will be seriously considered, including the gears, pistons, engine, and other moving parts. It is meticulously designed under the help of computer-aided drafting (CAD). The product is sturdy and tough. The cabinet body and parts are securely fastened with heavy duty cabinet screws to ensure very strong construction. As a wearing component, its excellent strength considerably lower maintaining costs.

We proactively conduct sustainable operations. For instance, we are constantly introducing advanced production technologies to reduce water waste and CO2 emissions.

Custom message