Company Advantages1. Laike undercarriage sprocket is well manufactured. The process is carried out by our workers who handle the preparation and cutting of materials with a bar chart table and use numerically controlled lathes, saws, grinding machines.

2. The manufacture of Laike undercarriage sprocket is of high efficiency. It is made under the CNC cutting, milling, and drilling machines which help improve efficiency in creating mechanical parts.

3. Laike undercarriage sprocket has to go through the following production stages which include materials preparation, turning/lathing with both traditional and CNC milling machines, wire EDM, adjusting and polishing, and mechanical assembly.

4. The product is of high precision. It is manufactured by a variety of specialized CNC machines such as a cutting machine, punching machine, polishing machine, and grinding machine.

5. The product features enough safety. It ensured that there were no sharp edges on this product unless they are required.

6. The product features strong tensile strength. The elongation and fracture point of the part has been tested at a constant rate while measuring the load.

7. The product is highly chemical resistant. It is treated with a protective chemical coating or with protective paintwork to prevent corrosion.

8. The product features good deformation resistance. When a sufficient load from a machine is applied to it, it will not happen to change shapes.

9. When people order this product for their company, they find it to work perfectly and, more importantly, they will find it to last you for a long time.

10. It absolutely fits well my machine. I am happy that the specifications are perfect to meet my needs. - Said one of our customers.

11. This is a favorable point for this product as it does not have any internal process so the noise decreases to zero.

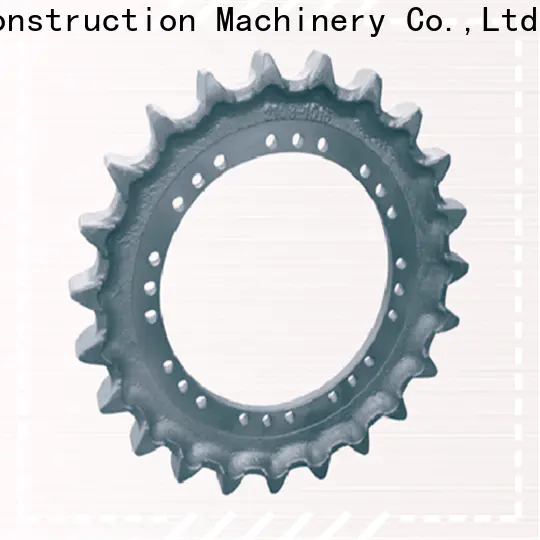

Laike custom excavator sprocket supplier for bulldozer

excavator sprocket

Type: