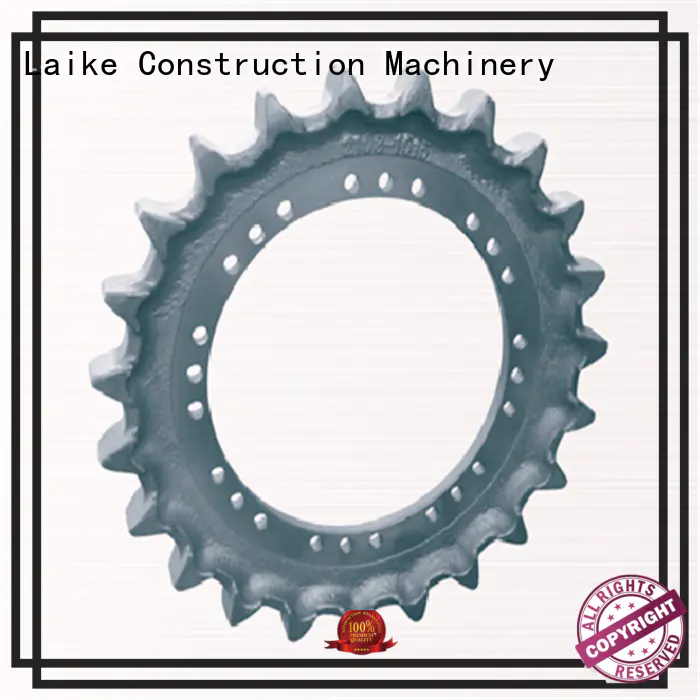

Company Advantages1. During the production, the quality of Laike dozer sprocket rim is strictly scrutinized in terms of materials, cutting, welding, turning, milling, grinding, and surface treatment.

2. Laike dozer sprocket rim has to go through the following production stages which include materials preparation, turning/lathing with both traditional and CNC milling machines, wire EDM, adjusting and polishing, and mechanical assembly.

3. During the production of Laike bulldozer sprockets , it has gone through heat and surface treatments: hardening, induction hardening, chemical browning, and electroless nickel plating.

4. Laike dozer sprocket rim has to go through several production stages. From the idea to the design through casting and processing, it is carried out by our professional workers.

5. Laike dozer sprocket rim is professionally manufactured with the help of CNC machines. This process is carried out by our highly qualified workers using turning, milling, and boring machines.

6. Laike bulldozer sprockets is treated well. It has gone through following procedures include slotting, straightening, micro-bead blasting, tumbling, ultrasonic and steam cleaning, as well as chemical and microdot marking.

7. The product does not have a drop stitching problem. A uniform yarn tension in the machine is ensured and yarn feed rate is regulated properly to guarantee consistent stitches.

8. This product stands out for its wrinkle recovery ability. Its fabrics are able to return its shape when it is twisted, wrinkled, or distorted in any way.

9. The product is safe to use. It has been checked under anti-static testing and materials elements inspection to ensure users' safety.

10. The product is resistant to corrosion. It has the ability to resist the impact of chemical acids, strong cleaning fluids or hydrochloric compounds.

11. This product features good moisture management. In the design phase, different degrees of sweating are simulated and corresponding parameters are determined (e.g. breathability, thermal insulation).

12. The product suits for various application and has a great market prospect as it is increasingly popular in the industry.

13. Our company's product serves a wide variety of applications in the field.

14. With all these features, it is greatly recognized by customers.

15. The product is well-known at home and abroad with so many advantages and features.

16. The product has accumulated numerous praises from customers in the industry.

Laike custom made bulldozer sprockets hot-sale for excavator

bulldozer sprockets

Type:stable performance、 Type1:handpick materials

、 Type2:reasonable design