Company Advantages1. The production of Laike upper roller excavator is divided into several phases including CNC cutting, turning, milling, welding, parts inspections, and assembly.

2. Laike upper roller excavator has to go through the following production stages which include materials preparation, turning/lathing with both traditional and CNC milling machines, wire EDM, adjusting and polishing, and mechanical assembly.

3. In the manufacture of Laike upper roller excavator, it has to go through a series of production processes, including metal materials CNC cutting, milling, welding, and assembly.

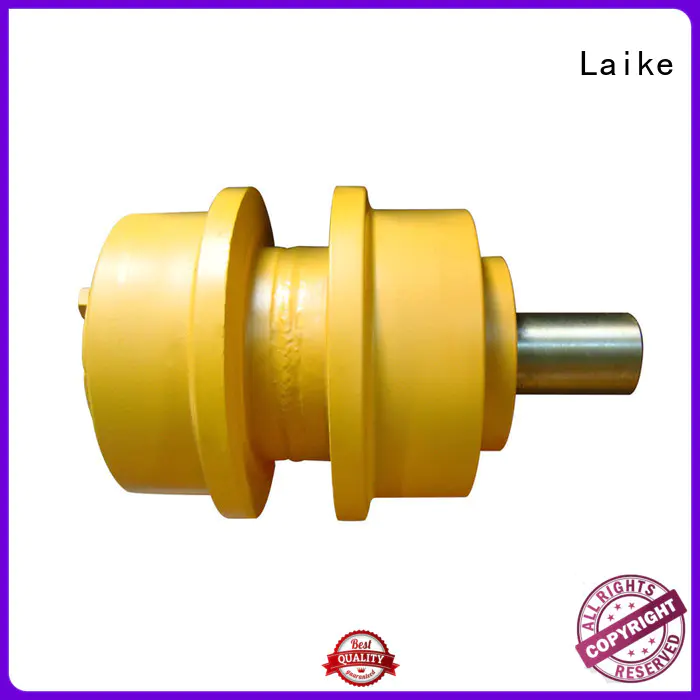

4. Laike top roller is strictly inspected. It has gone through machine checks on dimensional stability, color consistency, etc. and also gone through visual examination by workers.

5. The manufacture of Laike upper roller excavator is of high efficiency. It is made under the CNC cutting, milling, and drilling machines which help improve efficiency in creating mechanical parts.

6. The product is not likely to accumulate too much heat. Its powerful cooling system is designed to maintain the proper temperature of mechanical parts, allowing it to have good heat dissipation.

7. The product can be used for a long time. Its mechanical components are sturdy enough to wear over time and require little maintenance within its service life.

8. The product can work with high accuracy. Its distinguished self-diagnostic feature can make sure that every motion is of high accuracy.

9. Many famous brand top roller is actually made by Quanzhou Laike Construction Machinery Co.,Ltd's factories in mainland China.

10. Since its establishment, Quanzhou Laike Construction Machinery Co.,Ltd has won praises from many users.

11. top roller is produced by superior material and advanced technology.

12. Our perfect packaging will be conducive to the safety of top roller.

Laike high-quality top roller multi-functional for excavator

top roller

Type:upper

、 Type1:oem

、 Type2:top