Company Advantages1. The design of Laike sprocket segment is developed using a 3D CAD program. CAD models are created for the individual parts and the subassembly showing how the parts are connected together.

2. Laike undercarriage sprocket undergoes the following production processes: the preparation of metal materials, cutting, welding, surface treatment, drying, and spraying.

3. The manufacture of Laike undercarriage sprocket is of high efficiency. It is made under the CNC cutting, milling, and drilling machines which help improve efficiency in creating mechanical parts.

4. The production of Laike undercarriage sprocket has been optimized. It is produced with the help of modern IT-based processes such as the solidification simulation.

5. Laike undercarriage sprocket is constantly monitored. It is inspected by our trained staff who works exclusively to ensure the correct execution and dimensional control of the product that they are following.

6. Its quality is highly evaluated by authoritative testing organizations.

7. We take great pride in making products that will serve you for years.

8. sprocket segment has excellent quality and undercarriage sprocket feature.

9. The product is of the quality that meets with the regulatory requirements at home and abroad.

10. Quanzhou Laike Construction Machinery Co.,Ltd believes that our products can have a place in the world.

11. There are professional team in Laike with a relatively complete quality guarantee system.

12. By perfecting the quality guarantee of sprocket segment , Laike has received more high comments from customers.

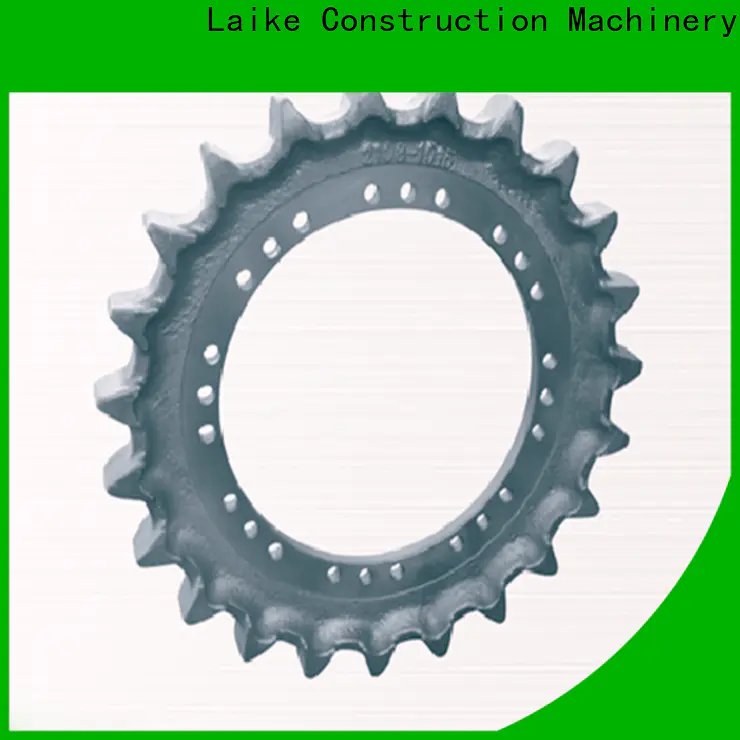

Laike new sprocket segment manufacturer for excavator

sprocket segment

Type: