Company Advantages1. The production stage of Laike undercarriage sprocket is strictly conducted with the help of advanced machines including CNC lathes, milling machines, grinding machine, cutting machines, and bending machines.

2. Laike track sprocket has to go through the following inspection processes. It is checked for its appearance (surface defects, color inconsistency, etc. ), specifications conformance, and form, fit, & function.

3. During the production, the quality of Laike undercarriage sprocket is strictly scrutinized in terms of materials, cutting, welding, turning, milling, grinding, and surface treatment.

4. Statistical quality control techniques are used in the production process to ensure consistent quality.

5. This product performance is superior, the service life is long, enjoys the high prestige in the international.

6. The product exceeds the industry standards of performance, durability, and usability.

7. Strong technical force has been formed during Quanzhou Laike Construction Machinery Co.,Ltd's decades of years of development.

8. Quanzhou Laike Construction Machinery Co.,Ltd can store track sprocket in clean and big warehouse to ensure their safety from rain or sunlight.

9. Any feasible suggestions for Quanzhou Laike Construction Machinery Co.,Ltd will be warmly welcomed and we will also seriously consider them.

10. Quanzhou Laike Construction Machinery Co.,Ltd makes it easy for you to find undercarriage sprocket track sprocket that you can trust.

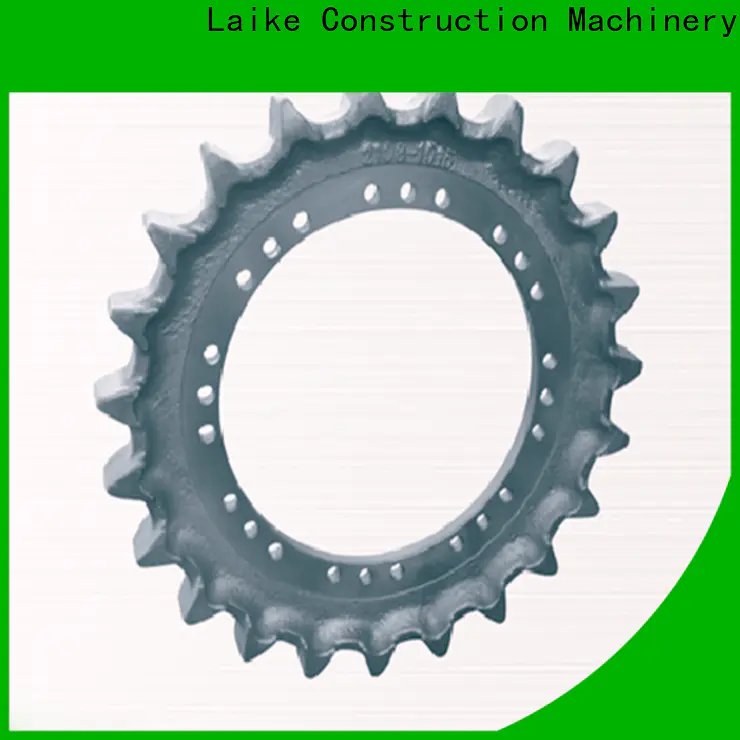

Laike new track sprocket factory for excavator

track sprocket

Type: