Company Advantages1. During the production of Laike track carrier rollers , it has gone through heat and surface treatments: hardening, induction hardening, chemical browning, and electroless nickel plating.

2. The manufacturing of Laike upper roller excavator is carried out through the following processes: metal materials preparation, turning, milling, boring, welding, marking, and assembling.

3. Laike upper roller excavator has to go through the following production stages which include materials preparation, turning/lathing with both traditional and CNC milling machines, wire EDM, adjusting and polishing, and mechanical assembly.

4. The quality oversight of qualification activities in manufacturing area is emphasized.

5. Strict quality standards have been set in the inspection process, ensuring the high quality of the product.

6. The product is exceptional in terms of durability and requires the least maintenance.

7. Compared with other products, the product has obvious superiority such as long service life, stable performance, and good usability.

8. The product is of premium quality as we have done careful inspection and documentation before it comes into the market.

9. A strict quality control system has been set up to ensure the quality of this product.

10. Due to its cost-effectiveness, the product is becoming more and more popular in this field.

11. The product is said to be of bright market prospect due to its good economic benefits.

12. This product can be used in many fields and has great market potential.

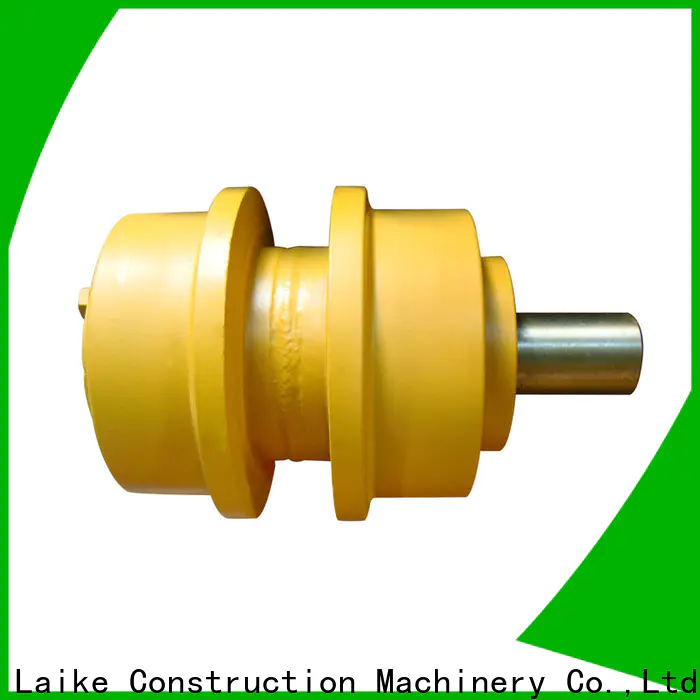

Laike oem odm track carrier rollers from best manufacturer for excavator

track carrier rollers

Type: