Company Advantages1. The manufacturing of Laike track drive sprocket is carried out through the following processes: metal materials preparation, turning, milling, boring, welding, marking, and assembling.

2. The production stage of Laike track drive sprocket is strictly conducted with the help of advanced machines including CNC lathes, milling machines, grinding machine, cutting machines, and bending machines.

3. In the manufacture of Laike track drive sprocket , it has to go through a series of production processes, including metal materials CNC cutting, milling, welding, and assembly.

4. The production of Laike track drive sprocket has been optimized. It is produced with the help of modern IT-based processes such as the solidification simulation.

5. The product is superior in terms of performance, durability, and so on.

6. The product is safe and reliable with great functions.

7. The overall quality of this product is ensured by our professional QC team.

8. Quanzhou Laike Construction Machinery Co.,Ltd pays attention to the quality of talents and intensive development of sprocket segment .

9. As a responsible sprocket segment manufacturer, Quanzhou Laike Construction Machinery Co.,Ltd pays more attention to the quality assurance of the product.

10. Laike is very famous for its high quality sprocket segment .

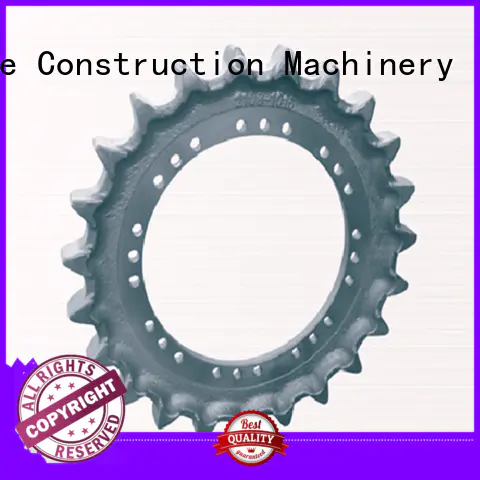

Laike reasonable design sprocket segment transfer engine power for excavator

sprocket segment

Type:reasonable design

、 Type1:stable performance、 Type2:handpick materials