Company Advantages1. During the production, the quality of Laike undercarriage sprocket is strictly scrutinized in terms of materials, cutting, welding, turning, milling, grinding, and surface treatment.

2. Laike undercarriage sprocket is constantly monitored. It is inspected by our trained staff who works exclusively to ensure the correct execution and dimensional control of the product that they are following.

3. Laike sprocket excavator is treated well. It has gone through following procedures include slotting, straightening, micro-bead blasting, tumbling, ultrasonic and steam cleaning, as well as chemical and microdot marking.

4. The product features remarkable energy efficiency. During production, it utilizes the newest latest energy conservation technologies to reduce energy consumption as possible.

5. The product poses no risk of electric shock. Having passed a dielectric voltage-withstand test, it is guaranteed that it can withstand high voltage.

6. The product has no sharp or protruding edges. It has been finely welded with full and smooth edges and surface during the production.

7. This product is durable. Its stitching is secure and the inconspicuous area is free from bulk and is flat and smooth.

8. The product is built to last. It has passed the anti-aging test in many aspects, including the PCB, conductors, and connectors.

9. The product fits the requirements of customers and has broad market potential.

10. With so many advantages, lots of customers have made repeat purchases, showing the great market potential of this product.

11. This product has a wide range of practical and commercial applications.

12. The product is highly demanded in the market, showcasing its broad market prospect.

13. The product can be widely applied to different fields.

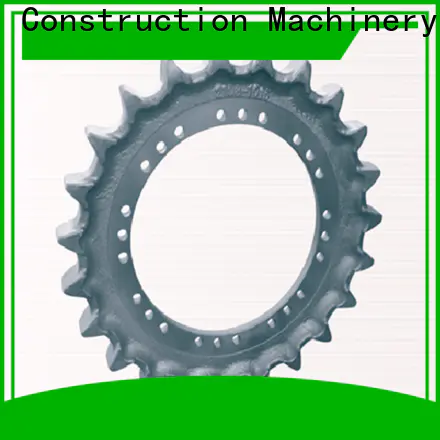

Laike sprocket excavator popular for bulldozer

sprocket excavator

Type: