Company Advantages1. The production of Laike bulldozer sprocket rim is divided into several phases including CNC cutting, turning, milling, welding, parts inspections, and assembly.

2. Laike bulldozer sprocket rim undergoes a series of production processes that involve prototyping, milling, turning, broaching, wire-cut electro-discharge machining (EDM), ultrasound wash, and assembly.

3. Laike sprocket segment is strictly inspected. It has gone through machine checks on dimensional stability, color consistency, etc. and also gone through visual examination by workers.

4. Laike bulldozer sprocket rim is professionally manufactured with the help of CNC machines. This process is carried out by our highly qualified workers using turning, milling, and boring machines.

5. The product is highly resistant to rust. Its surface has been treated with an oxide protective layer to prevent from the damage of wet environments.

6. The product features high accuracy. All its parts have been measured by means of the advanced 3D coordinate measuring device.

7. The product features enough safety. It ensured that there were no sharp edges on this product unless they are required.

8. All the features listed make this product ideal for living rooms or assembly rooms where multiple viewers can peek at the content on the screen clearly without any straining.

9. The product is found to run very smooth. It does not bother people by generating unwanting buzzing noises when operating.

10. The product helps save time for people's life or work. People don't have to take too much time to finish their work or enjoy a high level of living standard.

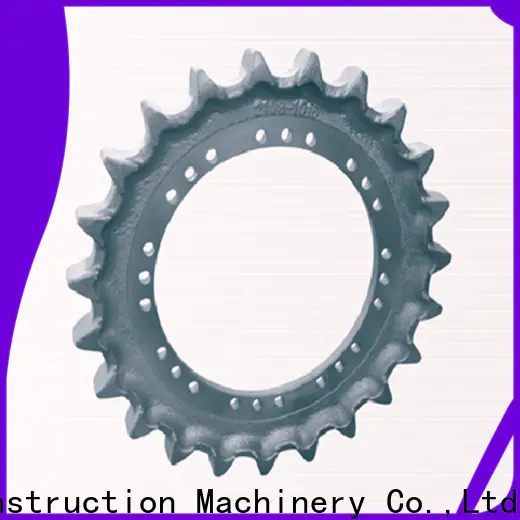

Laike sprocket segment supplier for excavator

sprocket segment

Type: