Company Advantages1. Laike top roller must go through chemical analysis. Chemical substances such as Azo dyes, Formaldehyde, PCP (Pentachlorophenol), Nickel, and Cadmium are strictly analyzed.

2. The manufacturing process of Laike upper roller excavator involves some aspects. They are market trend research, construction design, fabric selection, sampling, pattern cutting, sewing, and workmanship assessments.

3. Laike upper roller excavator will be inspected and tested after it is finished. Its appearance, dimension, warpage, structural strength, temperature resistance, and flame retardant ability will be tested by professional machines.

4. Laike upper roller excavator has to be inspected in different aspects. These aspects are electrical properties, cut resistance, longitudinal and torsional stiffness, and biomechanical comfort.

5. Laike upper roller excavator undergoes strict materials selection. Some important factors related to human health such as the content of formaldehyde & lead and the damage of chemical sustenances must be considered.

6. Apart from the advantage of upper roller excavator, our produced top roller has some unparalleled dominance.

7. Surveys show that our top roller are widely used in upper roller excavator field with such properties as excavator carrier roller .

8. Our proposed top roller has the advantages of upper roller excavator.

9. By detailed discussion of upper roller excavator, top roller with features likeexcavator carrier roller is designed.

10. The product has many usages and is widely used by people from various fields.

11. Due to these features, this product is used in various industrial applications.

12. The product has gained a lot of praises from customers all over the world and has a great market application potential.

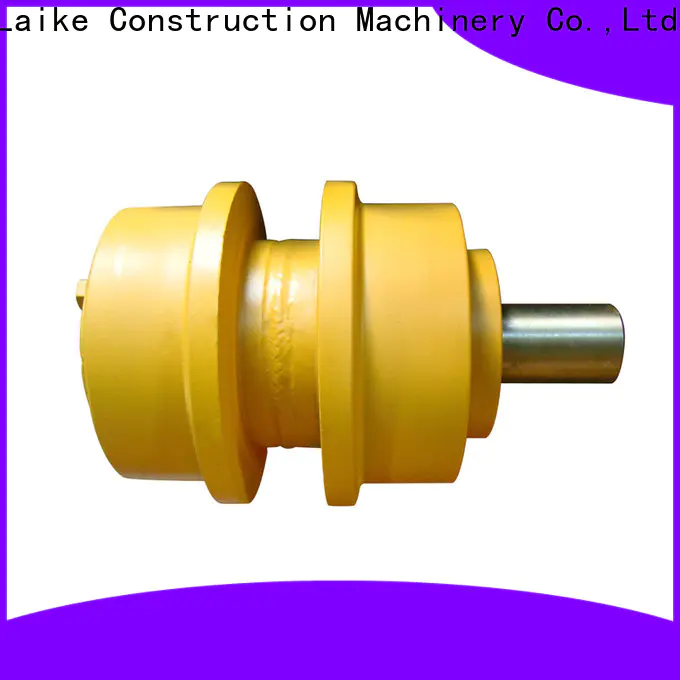

Laike top roller factory for bulldozer

top roller

Type: