Company Advantages1. Laike track chains for sale has to go through the following production stages which include materials preparation, turning/lathing with both traditional and CNC milling machines, wire EDM, adjusting and polishing, and mechanical assembly.

2. Laike track chains for sale undergoes a series of production processes that involve prototyping, milling, turning, broaching, wire-cut electro-discharge machining (EDM), ultrasound wash, and assembly.

3. The design of Laike track chain is developed using a 3D CAD program. CAD models are created for the individual parts and the subassembly showing how the parts are connected together.

4. The product is resistant to chemicals to some extent. Its surface has gone through special dipping treatment that helps resist acid and alkaline.

5. This product rejects odors and bacteria. Its surface contains an antimicrobial agent that inhibits the ability of microorganisms to grow.

6. This product features a stable construction. Its shape and texture are unaffected by temperature variations, pressure, or any form of collision.

7. This product is notable for its dimensional stability. Its dimensions will be not easy to change when it is torn frequently.

8. The product is assembled in high quality. Each component is being assembled according to the drawing & design to figure the part of the planned furniture.

9. Quanzhou Laike Construction Machinery Co.,Ltd has established several service centers for overseas customers.

10. Research & Development are the core competition of Quanzhou Laike Construction Machinery Co.,Ltd.

11. Leading in all directions, Laike's sales network is very comprehensive.

12. Overall, a high quality track chain always attracts many customers.

13. Being skilled at solving problems timely, Laike's service team has been trusted deeply by customers.

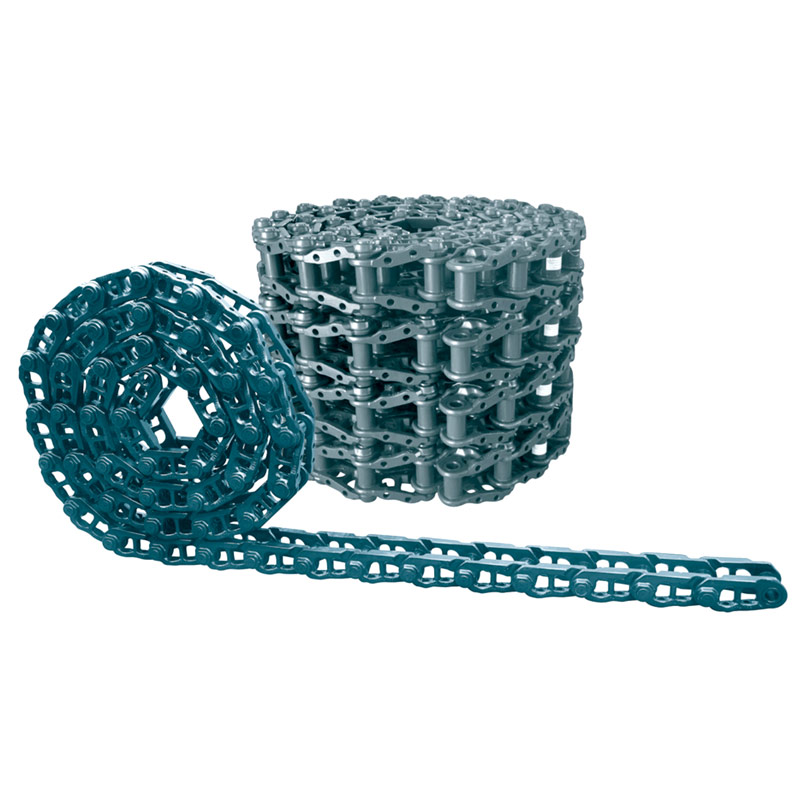

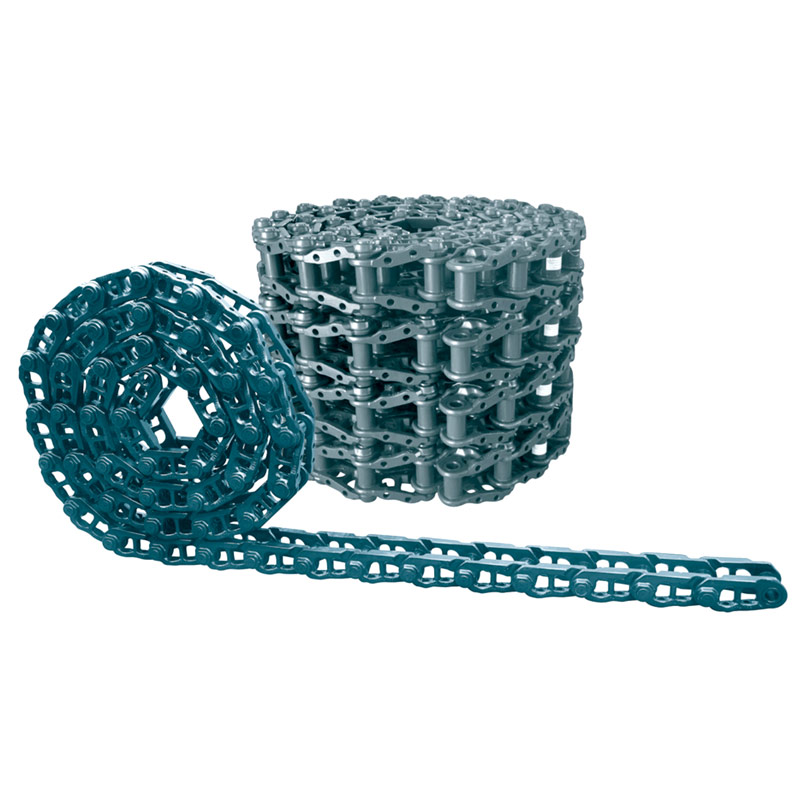

Laike track chain heavy-duty for excavator

track chain

Type: