Company Advantages

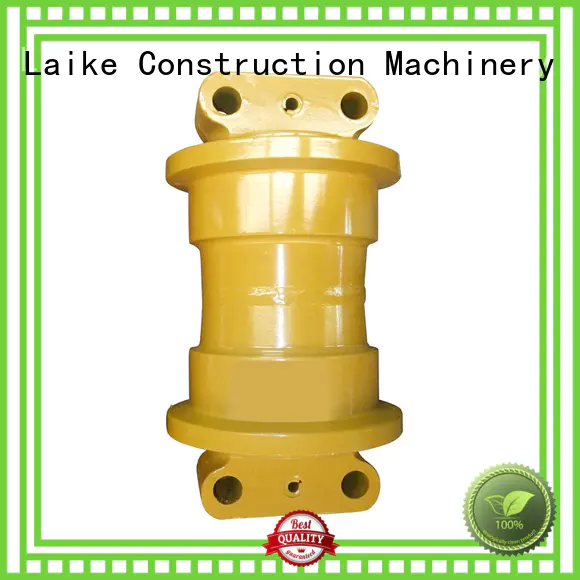

1. Laike lower roller uses materials certified by OEKO-TEX and CertiPUR-US as free from toxic chemicals which have been a problem in mattress for several years. It offers long life throughout abusive use

2. The product has got extensive use because of its high economic return. It is able to endure high operating temperatures

3. The product quality has been strictly controlled by professional QC team. Being heat treated and annealed during the manufacturing process, it has a stable dimension

4. The strong functionality of the product can be proved by the increasing sales. It can increase the flexibility of the bulldozer

Company Features

1. Quanzhou Laike Construction Machinery Co.,Ltd has been engaged in manufacture and sales of Quanzhou Laike Construction Machinery Co.,Ltd since the day of its establishment.

2. Quanzhou Laike Construction Machinery Co.,Ltd regards excavator bottom rollers technology as our core competitiveness.

3. We work hard to achieve our sustainability practices. We’ve put environmental criteria into our product innovation process so that every new product we launch contributes to sustainability.