Company Advantages1. In order to meet the standards of the textile industry, Laike track link for excavator is produced under strict quality control. We check and test the quality control of size matching, color fastness and color matte finish.

2. Laike track link for excavator has passed the flammability test. The testing principle is simple. The ignition source is applied to it in a standardized manner and any smoldering or combustion behavior is recorded.

3. Different machining approaches are used in processing mechanical parts of Laike track link for excavator . These mechanical parts, including engine, motor, and hydraulic components, will go through thermal treatment, honing machining, or wire cutting based on their actual usages and structures.

4. This product has the highest quality, performance and durability.

5. The product USES the reliable examination instrument to carry on the examination, guarantees the product quality to be reliable, the performance is good.

6. Our rigorous quality control processes ensure that our products are of good quality.

7. The product is inspected to ensure its high quality. The quality inspection plan is formulated by many experts and each quality inspection work is carried out in an orderly and efficient manner.

8. Adopt strict quality control system to provide strong guarantee for product quality.

9. Buying this product is a treat and one of the quickest and easiest ways to refresh a person.

10. This product is not easy to crinkle and crumple. People don't worry that their shape can't be kept after bending.

11. This product is not like a fabric that allows water to accumulate, germs and microbes. Instead, it is bacteriostatic.

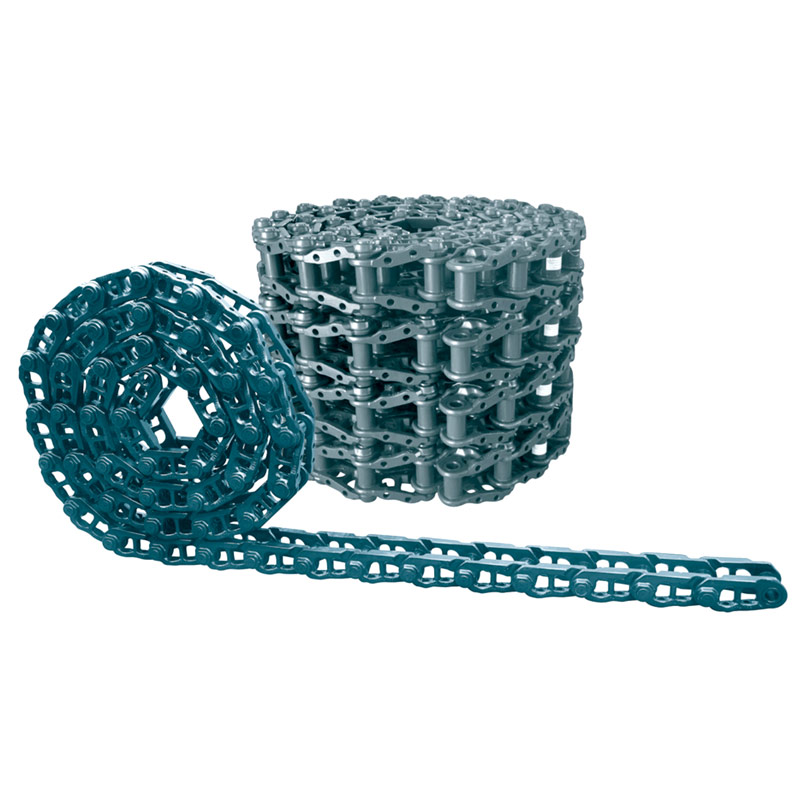

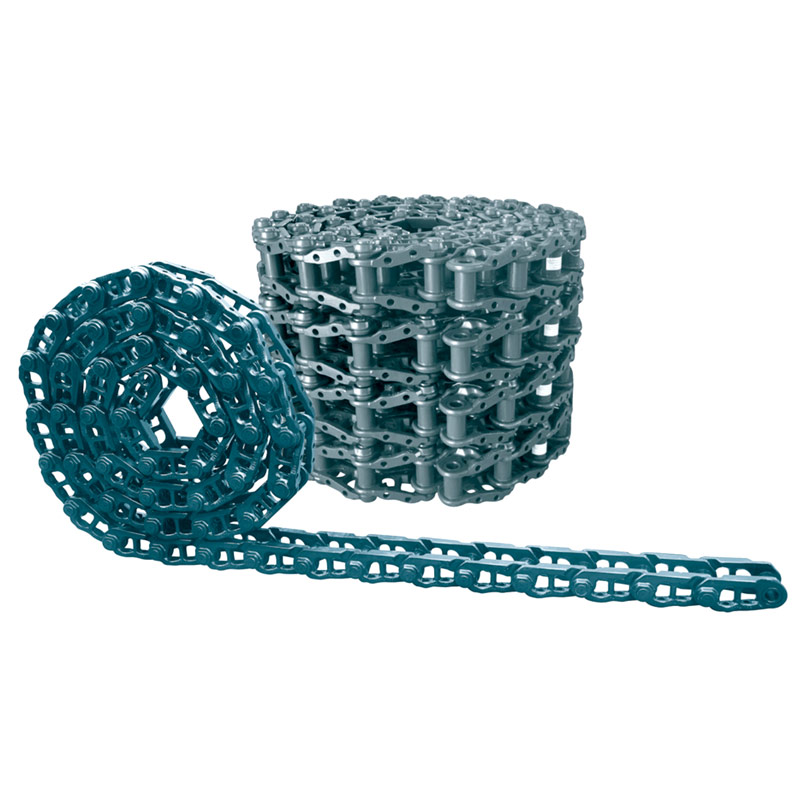

new track chain industrial for customization

track chain

Type: