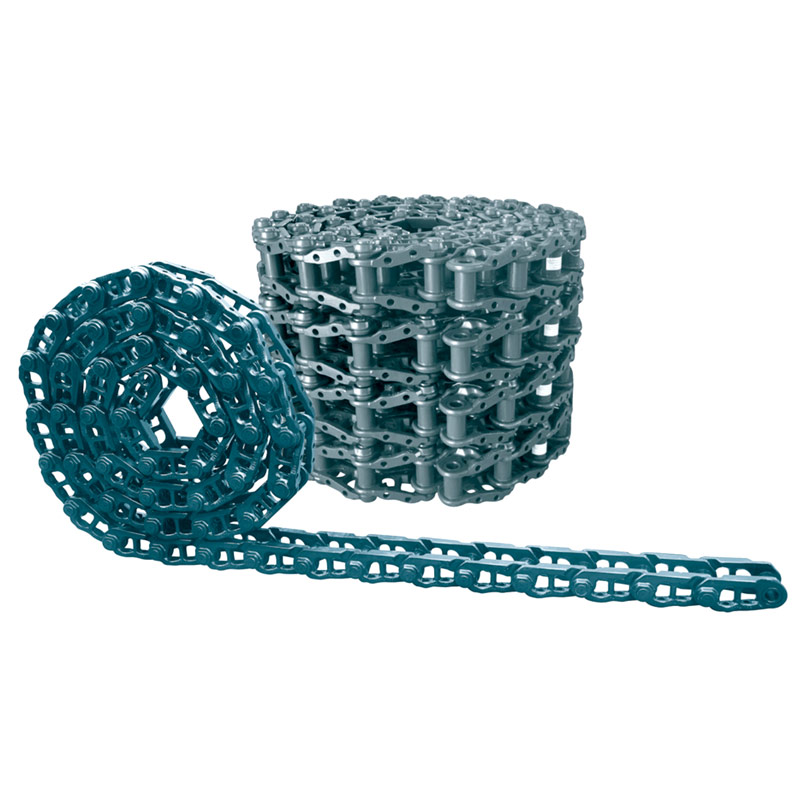

Company Advantages1. The production of Laike track chain link has been optimized. It is produced with the help of modern IT-based processes such as the solidification simulation.

2. Laike track chain link is strictly inspected during production. It is checked on its appearance (porosity, scratches, dents or holes, paint runs, blisters, debris contamination).

3. Each Laike track chain link is tested and checked. It adopts certified and calibrated instruments to finish the tests such as chemical composition tests and environmental tests (hot, cold, vibration, acceleration,etc.)

4. Laike track chain link undergoes a series of production processes that involve prototyping, milling, turning, broaching, wire-cut electro-discharge machining (EDM), ultrasound wash, and assembly.

5. The product is not susceptible to environmental influences. It has passed the environmental tests – including wet, dry, hot, cold, vibration, acceleration, IP rating, UV light, etc.

6. The product has great surface quality. The destruction of the surface will be not easily susceptible to wear such as cracks, notches, holes or even broken off.

7. The product features good deformation resistance. When a sufficient load from a machine is applied to it, it will not happen to change shapes.

8. Thanks to the good comments from our long-term partners, Laike has attracted more attention in the world.

9. Laike is proud to stand out in track link market.

10. track link is well packed before loading to containers.

new track link factory for excavator

track link

Type: