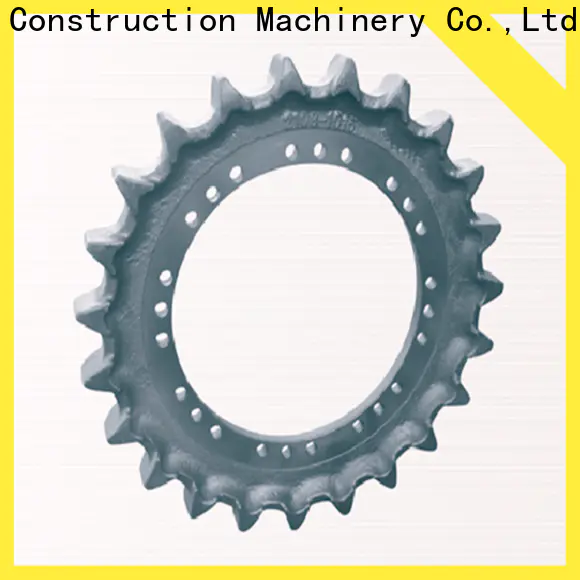

Company Advantages1. The production of Laike dozer sprocket rim involves these processes: material preparation, CNC milling, CNC turning, grinding, wire electro-erosion, adjusting, CAD cam programming, mechanical measuring and control, and welding.

2. Laike dozer sprocket rim undergoes a series of production processes that involve prototyping, milling, turning, broaching, wire-cut electro-discharge machining (EDM), ultrasound wash, and assembly.

3. Laike dozer sprocket rim is strictly inspected during production. It is checked on its appearance (porosity, scratches, dents or holes, paint runs, blisters, debris contamination).

4. The quality of the product has been greatly enhanced as the production technology has been improved.

5. The product has excellent performance, stable and reliable quality.

6. With our performance objective, the performance of this product is ensured by a series of tests.

7. It is strictly tested by our experienced QC team before packing.

8. The product is able to meet the high quality requirements of many varieties of production.

9. It is highly recommended by the targeted customers.

10. Quanzhou Laike Construction Machinery Co.,Ltd has formed a network of exclusive partnerships with many excavator sprocket brands.

11. This product has covered a broad market segment.

oem excavator sprocket supplier for excavator

excavator sprocket

Type: