Company Advantages1. The production phase for Laike excavator sprocket rim is going well. This phases includes yarn preparation, ginning, unwinding, cleaning, mixing, cleaning, and carding.

2. The safety level of Laike excavator sprocket rim meets international standards. It has passed various safety tests, including overload and overvoltage protection, electric leakage, short- and open-circuit protection, and so on.

3. Laike excavator sprocket rim has gone through the following production stages. They include the approval of drawings, the fabrication of sheet metal, welding, the arrangement of wire, and dry run testing.

4. Laike excavator sprocket rim is made of professional screen material. This kind of material is treated with plasticizers and stabilizers that make it a malleable material usable for technical applications.

5. The product has passed the strict quality inspection of the authoritative third parties.

6. Under the high demand on testing procedure, the product is guaranteed to be zero defect.

7. The demand for the product is exuberant due to its excellent performance and good durability.

8. It turns out to be effective that our QC team has been always focusing on its quality.

9. Our professional quality check team conducts strict quality inspections for the sake of high quality.

10. The product has consistent quality, stable performance, and long service life.

11. When people order this product for their company, they find it to work perfectly and, more importantly, they will find it to last you for a long time.

12. The product has relatively few moving parts, which means it will have a longer lifespan, which can be used for years.

13. 'This product is very easy to remove and re-install. It functions very well and fits well my machine.' - Said one of our customers.

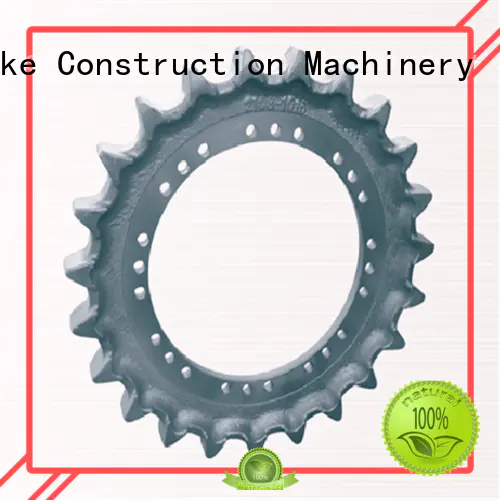

sprocket excavator handpick materials for bulldozer Laike

sprocket excavator

Type:handpick materials

、 Type1:reasonable design

、 Type2:stable performance