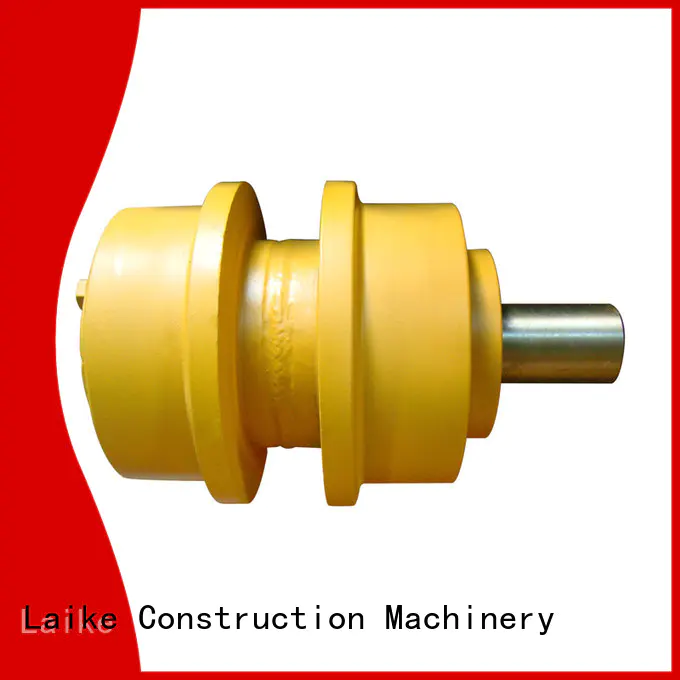

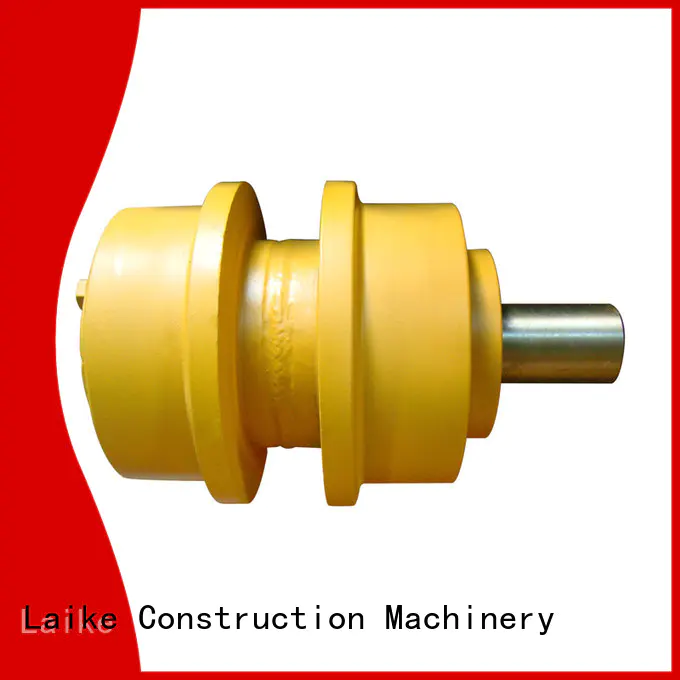

Company Advantages1. In the manufacture of Laike excavator carrier roller , it has to go through a series of production processes, including metal materials CNC cutting, milling, welding, and assembly.

2. Laike excavator carrier roller has to go through diverse tests. These tests include destructive or non-destructive testing, dimensional inspections, chemical resistance testing, and visual inspection.

3. The manufacture of Laike excavator carrier roller is of high efficiency. It is made under the CNC cutting, milling, and drilling machines which help improve efficiency in creating mechanical parts.

4. Laike excavator carrier roller has passed the following physical and mechanical tests. These tests include a strength test, fatigue test, hardness test, bending test, and rigidity test.

5. During the design of Laike excavator carrier roller , several design elements are taken into considerations. A good deal of emphasis is placed on tolerances, surface finish, durability, and practicability.

6. Laike top roller is developed in cooperation with our customers by our in-house engineers using CAD, 3D simulation, physics rendering, etc.

7. Our technical professionals are well aware of the quality standards set by the industry and test the products in a vigilant manner.

8. This product meets the stringent quality standards of the global market.

9. The product is inspected according to the industry standard to ensure no defect.

10. As well, clientele can purchase this product from us at low market prices.

11. The product has achieved a striding development in the market and will be more successful in the future.

12. This product has a wide reputation in the industry with its considerable features.

top roller wholesale popular for excavator

top roller

Type:wholesale、 Type1:oem

、 Type2:upper

、 Type3:top