Company Advantages1. Laike track carrier rollers is designed considering different factors. These factors such as the width & length of fabric, appearance, and fabric construction are ensured to comply with the garment standards and regulations.

2. Laike track carrier rollers has to go through a wide range of production stages. These stages cover research based on feet shape, CAD design, material cutting, stamping, sewing, and stitching, and assembly.

3. The design of Laike track carrier rollers is strictly conducted. It is carried out by our designers who think highly of parts and components safety, the whole machine safety, operation safety, and environmental safety.

4. Laike track carrier rollers has gone through strict inspections. They cover performance check, size measurement, material & color check, and hole, components check.

5. The stable performance and long lifespan make the product stand out from competitors.

6. Quality is what Laike product can do for customers.

7. All indicators of this product meet the requirements of international quality indicators.

8. track carrier rollers is effortlessly capable of track carrier rollers .

9. track carrier rollers has remarkable performance.

10. This product offered by Laike is considered very useful in the industry.

11. The product has earned a good reputation in the market and will be applied more in the future.

12. The offered product is used in a multitude of applications.

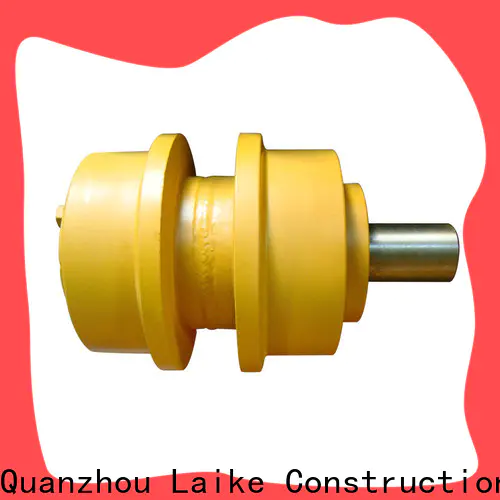

track carrier rollers supplier for excavator

track carrier rollers

Type: